Roll Die Cutting Machine MYC-950PY

Specs PDF

Specs PDF

Specs PDF

Specs PDF

| Model | Roll Die Cutting Machine MYC-950PY |

| Max Cutting Area | 940mmx510mm |

| Paper Gram Weight | 120-400g/m² |

| Air Pressure Requirement | 0.5Mpa |

| Weight | 6T |

| Max Cutting Pressure | 180T |

| Cutting Precision | ±0.15mm |

| Production Capacity | 160-200times/min |

| Air pressure consumption | 0.25m³/min |

| Total power | 12KW |

| Max Roller Diameter | 1600mm |

| Dimension | Heater Knurling |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

Through this video, we will showcase the die cutting machine 950PY. This machine is specifically designed for efficiently cutting various materials, ensuring superior performance. It can accurately cut materials into different shapes and sizes, meeting different cutting requirements.

More videos |

|

|

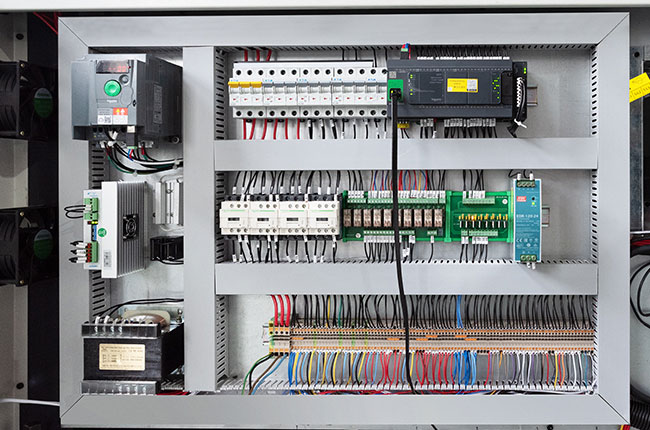

Electric System Using Schneider brand PLC control system , encoder angle detection and control, photoelectric tracking detection. realizing |

|

|

|

Servo Motor The coordination of the servo motor and the photoelectric eye can realize the color recognition and ensure the perfect match of the die-cutting position and the graphics. paper roll feeding length is controlled and fixed by Servo motor which guarantees the High precision of die-cutting and without any troubles |

|

|

|

Touch Screen lt adopts PLC controller and touch screen (man -machine interface) all the working parameters can be set up on the control panel which is convenient for parameter setting and adjusting.(easy to operate) |

|

|

|

Photoelectric Eye High sensitivity photoelectric eye color tracking Sensor assures thesynchronization of material feeding and die-cutting speed. |

|

|

|

Entity Induction Switch By the action of the entity induction switch, finished product will beautomatically lowered down to remain the height of the pilling paperunchanged, during the whole die-cutting process, manual paper-takingis not needed. |

|

|

|

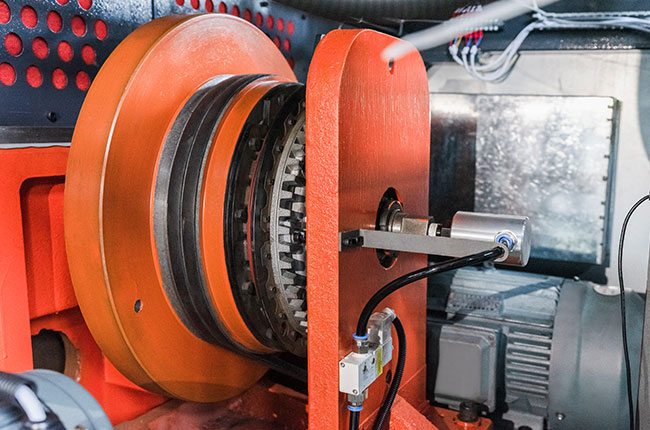

Inverter Motor The die-cutting force is provided by a 7.5KW inverter motor driver. It isnot only power-saving, but also can realize the stepless speed adjustmentespecially when coordinate with the extra large flywheel, which makethe die-cutting force strong and steady, and the electricity can be furthelreduced. |

|

|

|

Hydraulic Station It can support at least 1.5T pressure to load for Max roll paperdiameter 1.6m. |

|

|

|

Feeding Unit & Automatically Fold And Flatten By the action of the entity induction switch, finished product will beautomatically lowered down to remain the height of the pilling paperunchanged, during the whole die-cutting process, manual paper-takingis notneeded. It realized the multistage adjustment of the folding degree. No matterhow bent the product is, it can be flatten or refolded towards otherdirections. |