Paper Hamburger Box Making Machine MYC-9905

Specs PDF

Specs PDF

Specs PDF

Specs PDF

| Model | Paper Hamburger Box Making Machine MYC-9905 |

| Productivity | 60-160pcs/min |

| Sealing Method | Glue Sealing |

| Material | 200-600 g/m² Cardboard |

| Paper Thickness | Max 1.5 mm |

| Total Power | 5.6kw |

| Servo motor | 0.75KW |

| General motors | 2.2KW |

| Air Required | 6kg/cm²*200 L/min |

| Total Weight | 2200kg |

| Machine Dimension | 3600*1350*1500mm |

| Paper Box size | Length :100-450mm ,Angle :5°-40°

Width : 100-580mm ,Box Height : 15-200mm |

| Standard Machine

Blank Paper size |

Max 380*380MM(We can also according to customer's requirement to customize the bigger size if they need it) |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

Through this video, we will showcase the hamburger box machine 9905. This machine is specifically designed for efficiently manufacturing paper hamburger boxes, ensuring superior performance. It can produce hamburger boxes of various sizes, meeting different size requirements.

More videos |

|

|

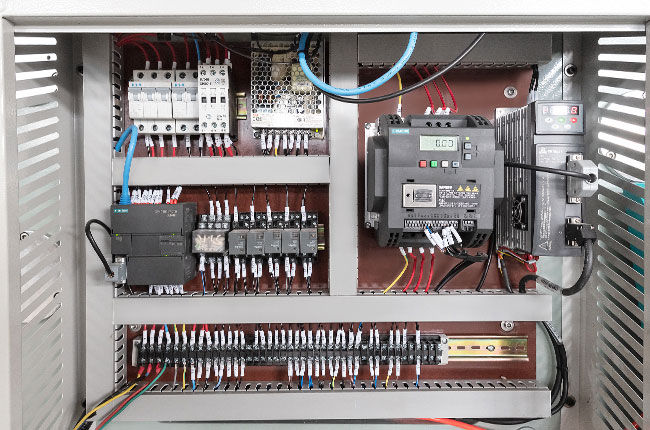

Power Systems Quality Brand electric System like Delta, Schneider.PLC control system be with Schneider Brand Made in France with Reliable quality |

|

|

|

Touch Screen lt adopts PLC controller and touch screen (man -machine interface)all the working parameters can be set up on the control panel whichis convenient for parameter setting and adjusting.(easy to operate) |

|

|

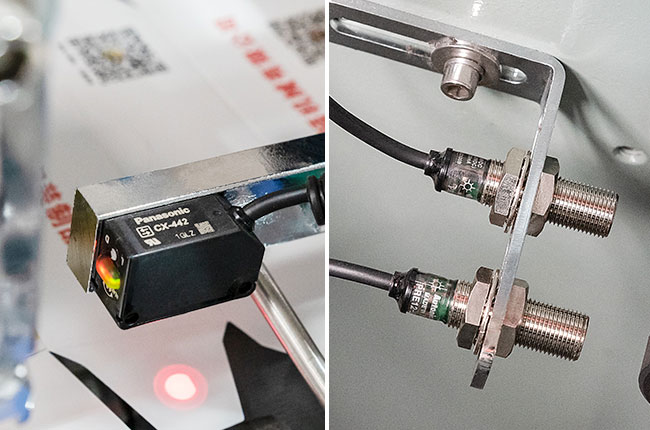

Detecting SensoThe machine will stop automatically if the failure detecting Sensorsdetect paper blocking or paper jam ,it can reduce paperconsumption , and improve the operation safety. |

|

|

|

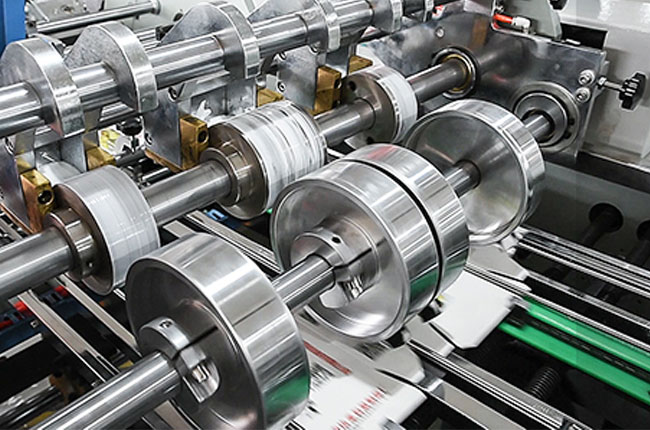

Servo Motor Paper feeding is controlled by chain and servo motor transmissionwhich can stable and fast speed . |

|

|

|

Gluing Unit High efficiency and high precision to feeding glue and the sealingedge of the carton. Food grade water-base cold glue is put in gluebox, When it is on running ,the gluing wheel touch glue by thepositioning foam.When no paper come through, glue part will lift upautomatically. |

|

|

|

Wooden Mould The mould can be customized designed easily for different paper boxdesign and size , cheaper price and easy to change. |

|

|

|

Main Motor lt is stronger power to drive the whole machine to run thetransmission function , better quality, long span life. |

|

|

|

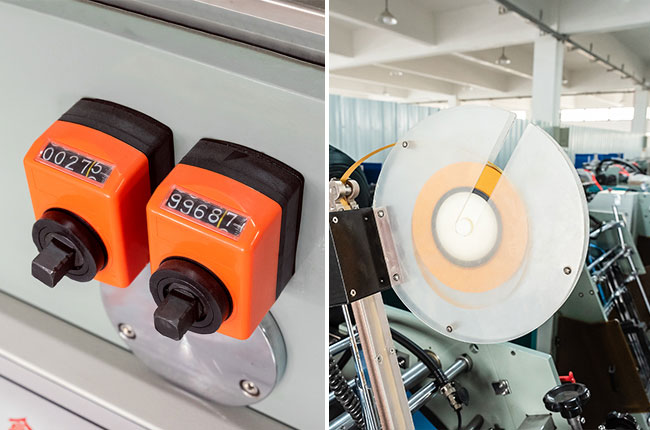

Storge Rack Width Adjusting Unit & Paper Tapes Counting Unit It is used to adjust the width of the storage rack to stack of papermaterials easily. lt is used to insert marks for counting product quickly and seperatethe box easily and accurately. |