High speed paper napkin machine MYC-CJ330

Specs PDF

Specs PDF

Specs PDF

Specs PDF

| Product Type | High speed paper napkin machine MYC-CJ330 |

| Speed | 1200pcs/min |

| Power Supply | 380V,three-phases |

| Finished Product Size | Open size 330*330 mm |

| Layers OfThe Paper | 2-3 layers 15 -18 g/ m² |

| Raw MaterialsMaximum Width | 340mm |

| Material Diameter | 1200mm |

| Inner Diameter ofRaw Paper Core | Φ76.2mm |

| Embossing | One set steel to paper |

| Folding Type | 1/4 |

| Power Consumption | 5KW (The host power: 2.2kW Cutter power: 0.55 KW) |

| Broken PaperFeatures | Embossed cut paper stop position |

| Printing Color | 1 or 2 color(optional device) |

| Counting | Electronic counter,pneumatic hop |

| Weight | 1100KGS |

| Machine Dimension | 1.9x1.3x1.12M175x1.17x1.6M(two packages) |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

In this video, we will present the napkin paper machine CJ330. This machine is specifically designed for efficiently manufacturing napkin paper, ensuring excellent performance. It is capable of producing napkin paper in various sizes, meeting different size requirements.

More videos |

|

|

Control Panel Simple and easy to operate, equipped with better quality switches and button , All the operation can be finished and controlled in this panel. |

|

|

|

Electric System Electrical System with high-quality brand electrical components stable and better quality. |

|

|

|

Raw Material Stand Raw paper roll can be put on this stand and paper unwinding bytransmission belt. |

|

|

|

Pattern Embossing Unit lt is adopted with steel to wool roller,pattern of the napkin can bemade according to the needs of users.Embossing pattern is clear andwill not loose layer. |

|

|

|

Folding Unit Folding board makes the paper be folded automatically before cutting. |

|

|

|

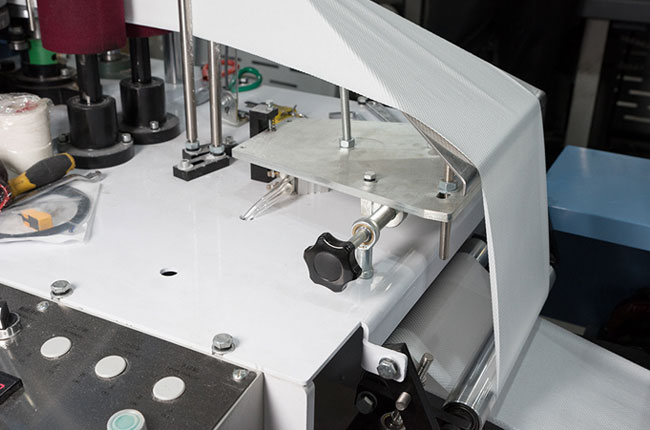

Cutter Unit Durable bandsaw cutter unit can cut the napkin faster,longer service life. |

|

|

|

Pneumatic Elements Air tac brand Pneumatic elements ,good quality stable and reliable. |