Automatic Paper Bowl Forming Machine MYC-W35

Specs PDF

Specs PDF

Specs PDF

Specs PDF

| Model | Automatic Paper Bowl Forming Machine MYC-W35 |

| Cup Side Welding | Ultrasonic heaterw |

| Paper Bowl Size | 6-35oz |

| Rated Speed | 70-80 pcs/min |

| Raw Material | Single/Double PE coated paper |

| Suitable paper weight | 140-350gsmu |

| Power Source: | 380V 50Hz |

| Total Power | 6 KW |

| Total Weight | 1980KG |

| Pack Size(LWH) | 2350 x1250 x1900MM |

| Air PressureRequirements | 0.6Mpa,output :0.6 m3/minute |

| Cup BottomHeating | 1side PE paper by heater knurling; 2side PE paper by cool device (circlewater) knurling |

| Cup BottomKnurling | Heater Knurling (if use single PE coated paper) |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

Through this video, we will showcase the manufacturing process and exceptional performance of the paper bowl machine W35. This machine is designed to produce paper bowls ranging from 6 to 35 ounces, catering to various size requirements..

More videos |

|

|

Power Systems Quality Brand electric System like Delta, Schneider.PLC control system be with Schneider Brand Made in France with Reliable quality |

|

|

|

Servo Motor The bottom paper feeding is controlled by servo motor and stepping motor, which greatly improve paper feeding in high precision and high efficiency way.(more stable ,less troubles and save bottom paper) |

|

|

|

Control Panel lt adopts PLC controller and touch screen (man -machine interface)all the working parameters can be setup on the control panel whichis convenient for parameter setting and adjusting.(easy operate) |

|

|

|

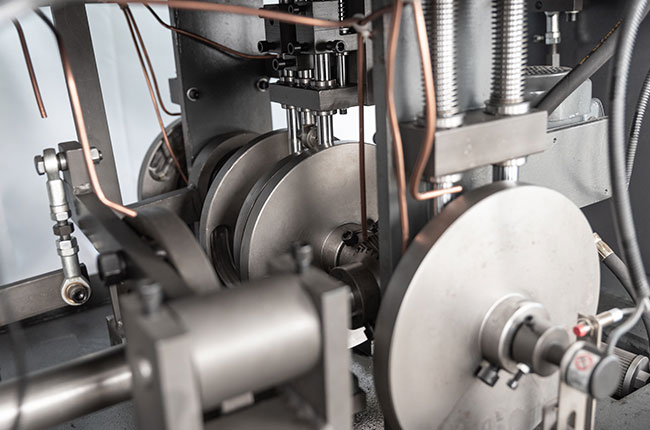

Multi-function CAM Three cams design are used to separately control the operation of thefour spare parts which makes paper fan sealing more stable at highspeed without troubles |

|

|

|

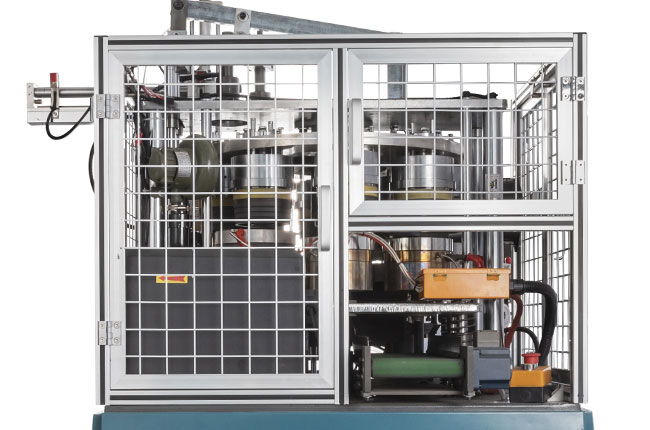

Safety Cover Protection during the operation of the machine |

|

|

|

Robot Hand Collecting And Counting System The finished bowls are picked up by the robot hand and countedautomatically, the packaging is more accurate and easier.There is no limit in size if it is used to pack multi sizes of bowls (the common counting system with tube requires the same top diameter), which greatly saves labor costs . |