01/04

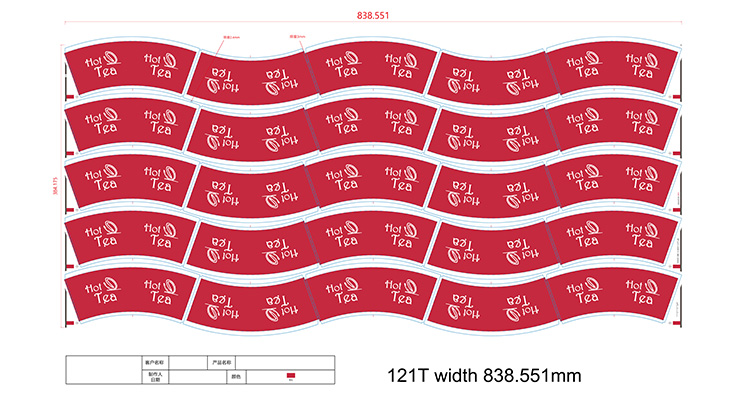

Flexographic Printing

Flexographic printing can achieve clear images and fine details, suitable for high-quality packaging and labels. The technology has a fast printing speed and can meet the needs of large-scale production.

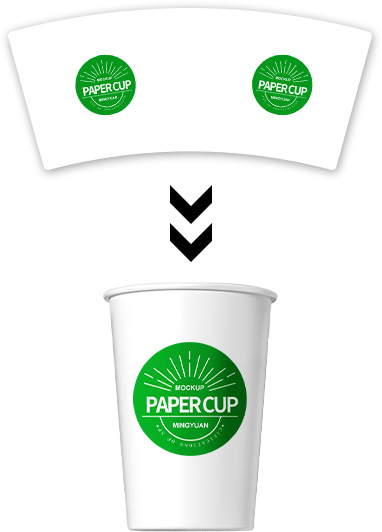

Paper cup fans are the raw material for making paper cups and are mainly composed of multiple layers of wood pulp paper. In order to improve the waterproofness, the surface of the paper cup fan is coated with special coating materials such as polyacetate (PLA) or polyethylene (PE).

During the production process, paper cup fans go through processes such as cutting, coating and drying to ensure uniform coating and prevent liquid penetration. Paper cup fans come in a variety of sizes and thicknesses to accommodate different shapes of paper cups.

Get A Quote

0+

Experience

3984m

Floor Space

134+

Current Employees

34

Machines

Comprehensive Understanding

PE Coated Paper Roll

6 Colors Printing

Printed Paper Roll

Die Cutting

Paper Fan

White Paper Cup

Printed Paper Cups

Double Wall Paper Cup

Production Chain

Please See Table

| Volume | From 3oz to 40oz |

| Paper Type | Single and Double PE coated paper |

| Paper Weight | 150-340gsm |

| PE Weight | 13-25gsm |

| Packaging | Palletized with plastic film outside And carton |

| Printing Type | Flexographic printing |

| Printing and color | Multicolor printing |

| Design Type | OEM、ODM |

| MOQ | 5 Ton |

Design your own product Everything is customized

consult

The customer clearly expressed his requirements for the size and design of the paper cups.

express delivery

Customers can choose to send existing samples so that we can accurately grasp their design requirements.

custom made

According to the needs and samples provided by customers, we design drawings of customized paper cups.

Full service Custom design

01/04

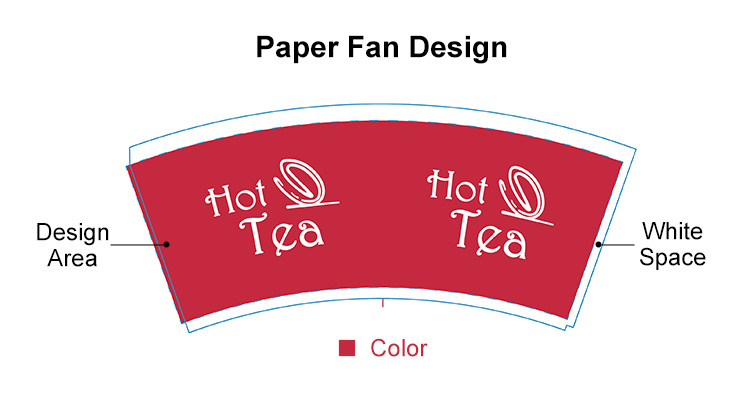

Flexographic Printing

Graphic Design Services

02/04

03/04

Knife Version Design

Printing Into Paper Rolls

04/04

This is called Pallet Packaging.A plywood pallet as the base, other one on the top. Protecting paper fan with any damage.

PE film wrapped inside.Protected against dirt,dampness and moisture.

PE coated paper is wrapped outside. The height of one pallet paper fan is 2.1 m.One pallet fan is 2 CBM (1.1m*0.9m*2.lm).

Shipping: we provide shipment service with FOB NingBo port, China or CIF destination port.

Multi-Angle

Food Grade Raw Material

Our paper fans are made of food grade raw materials, and can be single/double PE coated. Whether it is the paperboard, PE coated or the water-based ink used, all materials meet food grade standards.

Waterproof And Oil-Proof

Our paper fans have excellent oil and water resistance and edge permeability resistance. The strong bond between PE and paper ensures durability and reliability in wet and oily environments.

Virgin Wood Pulp

The paper we use is sourced from certified wood suppliers to ensure our paper fans have a natural color, zero paraben content.

Well Sealing

The paper cups made by our paper cup fans are strong and durable, and the bottom is specially designed to effectively prevent leakage. The excellent sealing performance.

95% of clients are concerned about the following issues

ALL RIGHTS RESERVED

Back to top

Privacy Poiicy

2022 RUIAN MINGYUAN MACHINERY CO.LTD ALL RIGHTS RESERVED.M-union.