Intelligent model double wall paper cup machine with counting MYC-DW100

Specs PDF

Specs PDF

Specs PDF

Specs PDF

| Model | Intelligent model double wall paper cup machine with counting MYC-DW100 |

| Paper Cup Size | 4-22 OZ(120-700ML)Mould exchangeable |

| Rated Speed | 180-350g/m PE coated paper,Gloss printed paper (gray based paper withgloss printing)Varnish PE coated paper fan or other film coated paperyua(can be welded by ultrasonic) |

| SuitablePaper Weight | 150-350gsm |

| Power Source | Power 6.5KW,50/60HZ,380V1220V |

| Total Weight | GW/NW: 2000KGS/1900KGS |

| Pack Size(L*W*H) | 2450*13USOOmm(Machine Packing Size)1250*860*1860MM(Counting system Packing) |

| Working Air Source Air | 0.8Mpa;Air Out-pyt:9.6m3/minute |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

Through this video, we will show you the manufacturing process and superior performance of the MYC-DW100 cup set. This machine can produce cup sleeves from 4 to 22 ounces to meet the requirements of different sizes.

More videos |

|

|

Control Panel lt is installed with PLC control system and touch screen , all parameterscan be set on the control panel, easy to operate. With auto failuredetection sensor , error information will be shown easily and that fortroubleshooting and maintaining |

|

|

|

Aluminum Mould With CNC Processing lt is best choice for high speed machine compared with the iron mouldlighter in weight and it is greatly improves the torque force of thespindle longer service life and better quality |

|

|

|

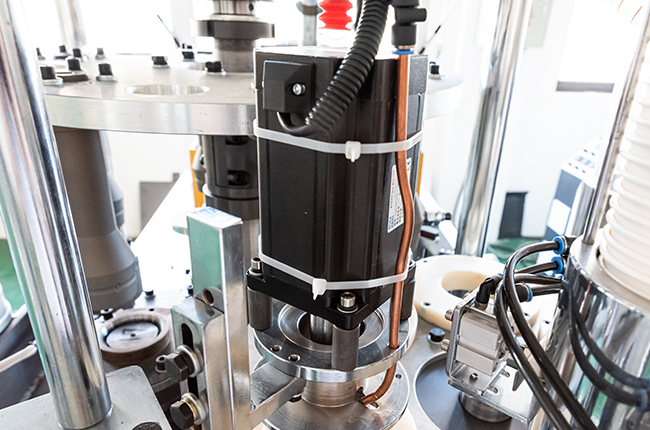

Gluing &Pasting Servo Motor The white glue will be sprayed by the motor to stick the sleeve andthe single wall.(Rotary glue spraying) |

|

|

|

Oil Lubrication And Circulation Oil lubrication system (Oil Pump Motor, The whole machine isequipped with automatic lubrication system which makes allmechanical parts working much more smoothly, longer serviceMACGINERYlife and less troubles. |