MYC-100A Automatic High Speed Paper Cup Making Machine

Specs PDF

Specs PDF

Specs PDF

Specs PDF

MY-100A high speed paper cup machine speed is 120-150 pcs/min and with two turnplate, open cam design and gear transmission. it is with auto paper fan feeding unit , PLC control system, bottom is sealed by Swiss Leister hot air device .

Auto oil lubrication can ensure all mechanical parts work smoothly and it can stop working automatically if the sensors detect failures, it can greatly improve operation safety.

MY-100A high speed paper cup machine can finish the whole process including paper feeding, cup side sealing, cup bottom punching & feeding, heating, knurling, rotary heating curling, cup counting and collecting.

| Model | MYC-100A Automatic High Speed Paper Cup Making Machine |

| Paper Cup Size | 6~16 OZ 16~22 OZ |

| Rated Speed | 120-160pcs/min ( Speed affected by cup size, paper quality & thickness)9OZ.280GSM paper cup Stable running speed 120 pcs each min. |

| Raw Material | One or Two side PE coated Paper(Popular for Hot and Cold drink Cups) |

| Suitable paper weight | 140-350gsm |

| Power Source: | 50/60HZ,380V1220V( better use 380V,3 Phase )or special Power requirement. |

| Total Power | 10KW |

| Total Weight | 3600KG |

| Pack Size(LWH) | 2730*1600*1800mm |

| Working Air Source | Air pressure:0.4Mpa:

Air Out-put:0.6m/minute Need to buy Air Compressor(by user) |

| Cup Side Welding | Ultrasonic heater |

| Cup Bottom Heating | 1side PE paper by heater knurling;

2side PEpaper by cool device (circle water) knurling |

| Cup Bottom Knurling | Heater Knurling (if use single PE coated paper) |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

Through this video, we will show you the paper cup manufacturing processand superior performance of 100A. This machine can produce cupsranging from 6 to 22 ounces, meeting various size requirements.

More videos |

|

|

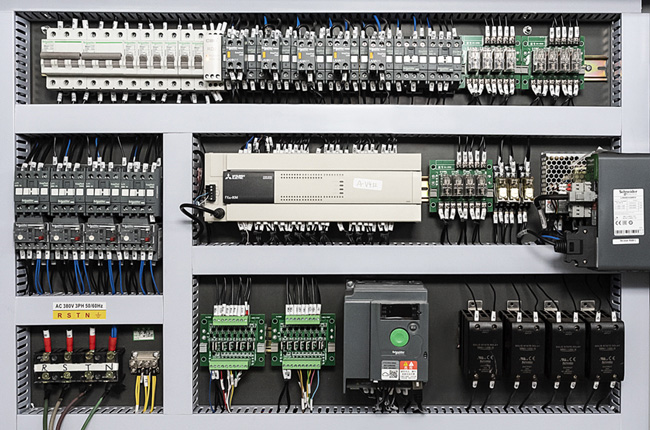

Electric System Quality Brand electric System like mitsubishi, Schneider.PLC controlsystem be with mitsubishi Brand Made in Japan with Reliable quality. |

|

|

|

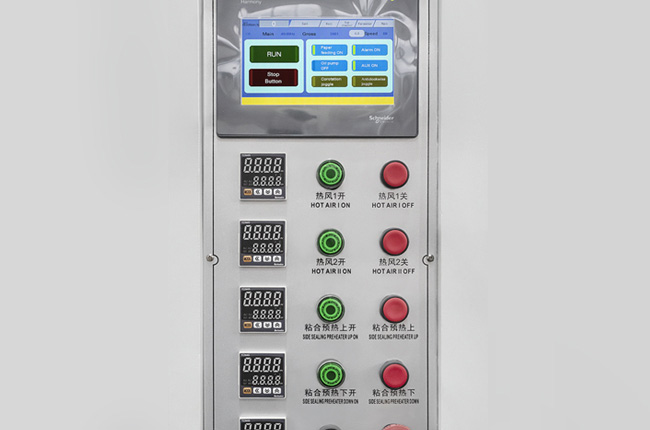

Schneider Touch Screen lt adopts PLC controller and touch screen (man -machine interface)all the working parameters can be setup on the control panel whichisconvenient for parameter settingand adjusting.(easy operate) |

|

|

|

Swiss Brand Hot Air Heater 2 pcs The molds with sleeve and bottom will be heated twice by the hot airguns. And then the end of the sleeve will be pre-folded inward to get ready for seaing with the paper cup bottom. |

|

|

|

Bottom Knurling And Sealing Unit New separate moving knurling unit design can increase the runningspeed and make bottom knurling perfectly without leakage. |

|

|

|

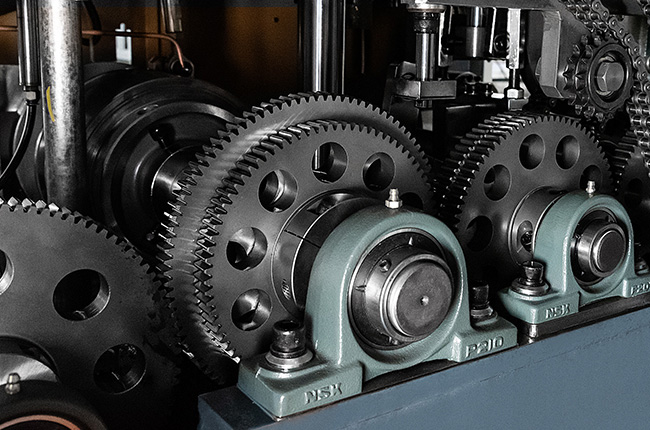

High-precision Transmission System All transmission mechanical parts are strictly selected from specificmaterials, and have undergone specific processing processes suchas surface phosphating, blackening, carburizing and quenchingand curve grinding to ensure that the machine has good stabilityand service life after careful assembly. |

|

|

|

Rotary Robot Hand Feeding Cup Body Three rotary robot hands catch and feed cup body to the mould inhigh efficiency and accuracy. |

|

|

|

Oil Pump Motor The whole machine is equipped with automatic lubrication systemwhich makes all mechanical parts working much more smoothly. |