High Speed Paper Plate Machine MYC-ZDJ1000

Specs PDF

Specs PDF

Specs PDF

Specs PDF

| Model | High Speed Paper Plate Machine MYC-ZDJ1000 | |

| Working Stations | Single Stations | |

| Double Stations | ||

| Paper Plate Size | 3-16 inch (mold exchangeable) | |

| Raw Material | Paper/paperboard,Aluminum foil coated paperOne side PE coated paper or other | |

| Suitable PaperWeight | 100-500 gsm (gram a square meter) | |

| Rated Productivity | 50-70 piece/minute(about 3000--4200pcs per hour) | |

| 100~120 piece/minute(about 6000--9000pcs per hour) | ||

| Power Source | 380V 50Hz or other required | |

| TotalPower | 7 KW | |

| 8.5KW | ||

| Total Weight | 1000 Kg | |

| 2000 Kg | ||

| Package Size(LxWx H) | 1.85m x 0.72m x 1.8m | |

| 3.0m x 1.7m x 1.7m | ||

| Oil Cylinder | MI-63-125-5t-xFlow:0.3 m3/ minOil pressure:Mpa0.3-0.6Cylinder stroke: 125 mm | |

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

Through this video, we will show you the manufacturing process and superior performance of the paper plate machine ZDJ1000. This machine is capable of producing paper plates ranging from 3 to 16 inches, with the ability to exchange molds for different size requirements.

More videos |

|

|

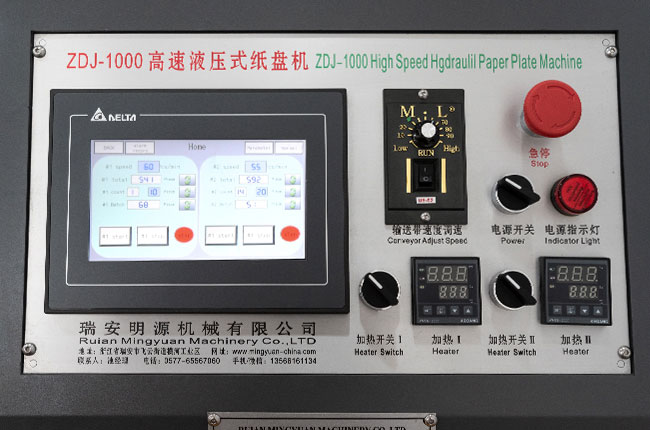

Power Systems Quality Brand electric System like Delta, Schneider.PLC control system be with Schneider Brand Made in France with Reliable quality |

|

|

|

Sensors Sensor failure detecting and it stops working automatically if themachine has any problem, it can greatly improve operation safety The error information will be shown in the PLC touch screen andremind the operator to solve the trouble.(good for machine maintaining) |

|

|

|

Touch Screen lt adopts PLC controller and touchscreen (man -machine interface)all the working parameters can beset up on the control panel which is convenient for parameter setting and adjusting.(easy operate) |

|

|

|

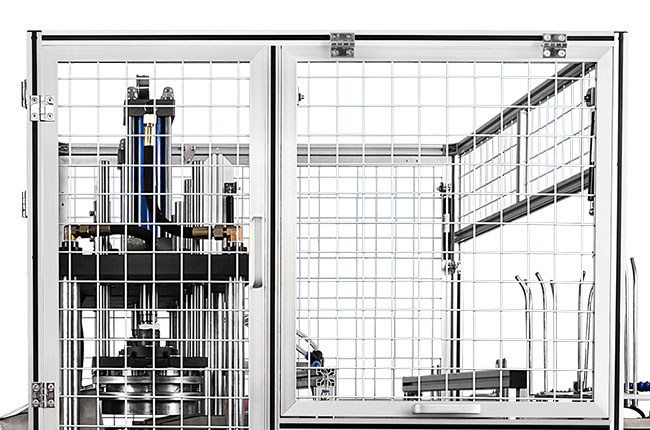

Hydraulic System hydraulic oil recycling ,it requires less air and energy saving , Keep sure stable forming plate.Normal hydraulic Cylinder pressure is up to 5T to meet the requirements of different thickness paper plate forming.it is adopted with fan cooling system to Reduce the temperature and make it longer service life. |

|

|

|

Plate Forming Mould Better quality durable mould ,longer service life. the mould designcan be customize as customers requirement |

|

|

|

Safety Cover Machine is installed with safety cover to protectthe operator and make the operation safer. |