ZDJ-1200High-speed Full Servo Motor Dirven Cardboard Machine

|

Model |

ZDJ-1200High-speed full servo motor dirven cardboard machine |

|

workstation |

Dual Station |

|

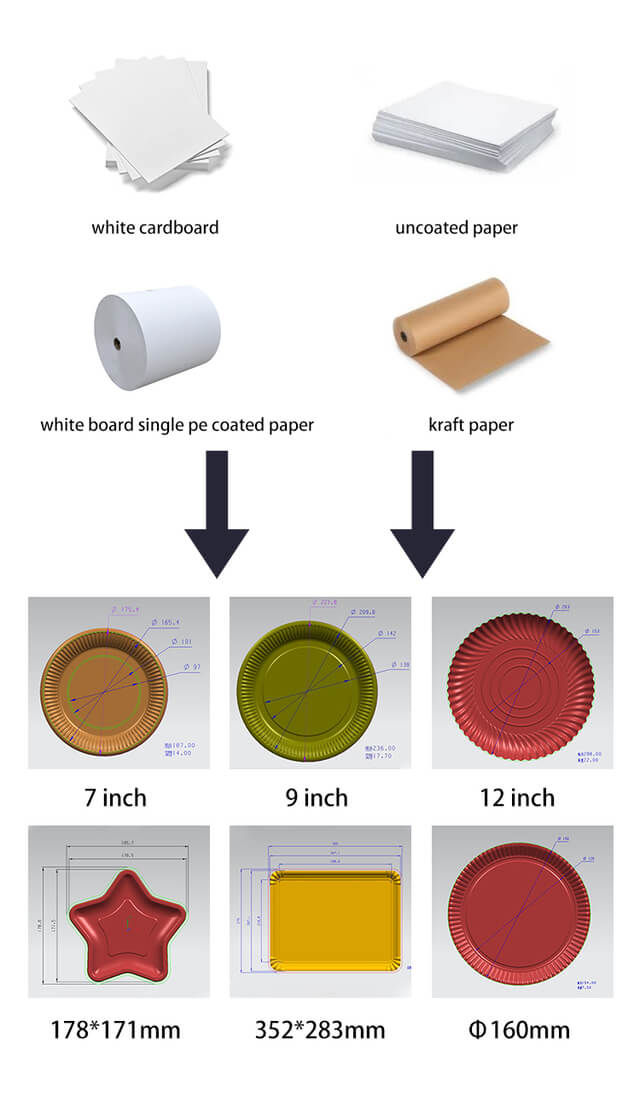

Paper size |

2-12 inches (mold can be replaced) |

|

raw materials |

Paper/paperboard. Aluminum foil coated paper, single-sided PE coated paper or other |

|

Suitable paper weight |

100-500 gsm |

|

Production speed |

120 ~ 140 pcs/min (7200-8400 pcs/h) |

|

power supply |

380V, 50160HZ or other requirements |

|

Total Power |

8.5 kW |

|

gross weight |

2000 kg |

|

Packing size (L x W x H) |

3000mm x 1700mm |

|

Air pressure |

MI-63-125-5t-x, flow rate: 0.3 m3/min, oil pressure: Mpa 0.3-0.6, cylinder stroke: 125 mm |

|

Our factory welcomes OEM orders (customer company name will be displayed on the machine panel) |

|

Our engineer team will send the operation video to guide you tcsolve the problem .if the spare parts is broken in the warrantyperiod, we will send you the new replacement parts for frec.

Raw materials : Single /double PE coated paper fan which isalready cut and printed , bottom paper roll

PS: Machine is without printing and cutting function(onlycan cut bottom roll paper, it can not cut the paper fan )

One machine is installed one full set mould for free. You canbuy extra half set mould (easy to change) or full set mould(difficult :1% success rate). We only recommend to change1-3 sets half set mould (with same bottom diameter size)in one machine.

Food grade or silicone oil and a small air compressor.

The machine will be finished installation and tested runningperfectly before the delivery . You will get the completemachine which is finished installation. We will provide the fulloperation and training Videos to guide you to run the machineAnyone can install the machine and operate it easily.

|

|

|

Electric System: Quality Branded Electric Systems such as Delta, Schneider,Innovance |

|

|

|

Control Panel: It adopts PLC controller and touch screen (man -machine interfaceall the working parameters can be setup on the control panel whichis convenient for parameter setting and adjusting.(easy operate) |

|

|

|

Robot hand auto paper feeding unit(servo driving): Robot hand auto paper feeding unit(servo driving)it is adopted with robot hand to feed the paper automaticallyit is driven by servo motor , more accurately and less issues |

|

|

|

Counting & Collecting System: The counting &collecting system with sorting function can stack thefinished paper plate in order, which is convenient for packaging andsave the labor costs |

|

|

|

8 Servo motor: There are 8 servo motors installed ,which ensure all the movement accurately and stably ,inlcuding plates pre-feeding , sucking , transferring and collecting |