Rated Speed: 160-180pcs/min

Paper Cup Size: 4 -16 0Z

Raw Material: PE/double PE/PLA laminated paper,Aluminum foil paper

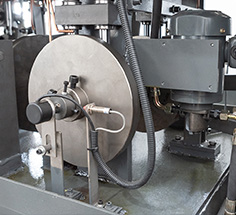

Cup Side Welding:Ultrasonic heater

Configure the power:35KW

MINGYUAN Paper cup machine is equipped with two turntables, Stable running speed 120-150pcs each min. The cup size can make 6~22oz, The machine comes with PLC control system, sensor failure detecting and it can safety. The whole machine adopts oil lubrication and circulation system, servo motor, Open cam drive and full gear drive system, which make it more accurate and stable.

Usually we will let customers know their local market to choose the popular size of the local market to start. Then we design paper cup drawings for you, custom machinery.

Within the manufacturing range of the paper cup machine, as long as the mold can be replaced. Different Size Cups with different bottom diameter and angle(Difficult to change mould).We NO Suggestion Client to changeFull Set Mould which easy be trouble of machine.For One Setmachine is better goes with 1-2 extra half sets mould.

14 years of experience in paper cup forming, Mingyuan Machinery is committed to delivering outstanding quality in the paper cup machinery field. We possess an in-depth understanding of the industry, relentlessly pursue technological innovation, and provide efficient, reliable solutions for paper cup forming. Choosing Mingyuan Machinery means choosing cutting-edge technology in the paper cup forming field.

Whether you need a fully servo paper cup machine, a mechanical paper cup machine, paper cup forming machines, paper cup manufacturing machines, or even paper cup outer sleeve machines and paper cup production equipment, we can meet your diverse requirements. Opt for flexible production, enhance your efficient production line, and elevate your production efficiency for greater business success.

Rated Speed: 160-180pcs/min

Paper Cup Size: 4 -16 0Z

Raw Material: PE/double PE/PLA laminated paper,Aluminum foil paper

Cup Side Welding:Ultrasonic heater

Configure the power:35KW

Rated Speed:130-150 pcs/min

Paper Cup Size:4-16 0Z

Raw Material: Single PE/double side PE:PLA coated paper cups,aluminum foil paper

Suitable paper weight: 140-300gsm

Power Source: 50/60HZ,380V/220V(better use 380V,3 Phase )or special Power requirement.

Total Power: 15 KW

Rated Speed:140-160 pcs/min

Paper Cup Size:1.5 ~16 OZ (Mould exchangeable, Max Cup Height: 136mm , Max Bottom width: 80mm)

Raw Material: One or Two side PE coated Paper, PLA paper, Aluminum foil, Plastic-free paper (Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ, 380V/220V(better use 380V,3 Phase ) or special power requirement

Total Power: 20KW(Stable Runnung Consumption 12KW)

Rated Speed: 80-100pcs/min

Paper Cup Size: 1.5 -16 0Z

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power requirement.

Total Power: 8.5 KW

Rated Speed:100-110pcs/min

Paper Cup Size:1.5~16 OZ

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power requirement.

Total Power: 8.5 KW

Rated Speed:90-100 pcs/min

Paper Cup Size:1.5-9 0Z

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ,380V/220V ( better use 380V.3 Phase )or special Power requirement.

Total Power: 4.8-5 KW

Rated Speed:120-160pcs/min ( Speed affected by cup size, paper quality & thickness)

Paper Cup Size:6~16 OZ,16~22 OZ

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power requirement.

Total Power: 10 KW

Rated Speed:1.5 -16 0Z

Paper Cup Size:100-110pcs/min

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ, 380V/220V ( better use 380V, 3 Phase ) or special Power requirement.

Total Power: 8.5 KW

Rated Speed:95-105pcs/min

Paper Cup Size:2-16 0Z

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ,380V/220V ( better use 380V.3 Phase )or special Power requirement.

Total Power: 5 KW

Rated Speed:100-120pcs/min

Paper Cup Size:1.5-9 0Z

Raw Material: One or Two side PE coated Paper(Popular for Hot and Cold drink Cups)

Suitable paper weight: 140-350gsm

Power Source: 50/60HZ,380V/220V ( better use 380V.3 Phase )or special Power requirement.

Total Power: 6KW

Rated Speed:80-100pcs/min

Paper Cup Size:4-22oz

Raw Material: 180-350g/m PE coated paper,Gloss printed paper (gray based paper withgloss printing)Varnish PE coated paper fan or other film coated paperyua(can be welded by ultrasonic)

Suitable paper weight: 150-350gsm

Total Weight: GW/NW: 2000KGS/1900KGS

Total Power: 6.5 KW

Speed:50-60 pcs/min

Paper Specifications: PE coated paper,Gloss printed paper (gray based paper with gloss printing).other film coated paper (can be welded by ultrasonic)

power supply: 50/60HZ 380V/220V ( better use 380V, 3 Phase ) or special Power requirement

General Power: 4 KW

Prevent wet air with water fromentering solenoidvalve, longer service life,more stable and better.

The whole machine adopts automatic oil lubrication system(oil circulation system is including oil motor, filter, copper pipe )which makes all gear moving parts working at high speed much moresmoothly and greatly lmprove the service life of spare parts

It adopts PLC controller and touch screen (man -machine interface)all the working parameters can be setup on the control panelwhich is convenient for parameter setting and adjusting.(easy operate)

It can cool the mould easily andmake the cup discharge easily

Unique shell design tailored to your brand's aesthetics for a distinctive paper cup machine appearance.

Seamless integration of your brand logo into machine design.

Customized pattern designs to suit your preferences.

Tailored molds for diverse cup sizes and shapes.

Voltage customization for perfect machine compatibility.

Personalized assembly line automation enhances production efficiency and management ease.