Rated Speed:120 ~ 140 pcs/min (7200-8400 pcs/h)

Paper Plate Size:2-12 inches (mold can be replaced)

Suitable Paper Weight:100-500 gsm

Power Source:380V, 50160HZ or other requirements

Total Power: 8.5KW

MINGYUAN paper plate machine has a stable running speed 100-140 pieces per minute, and the paper plate size produced is 2-16 inches. Equipped with a hydraulic system and hydraulic cylinder, it can press and form plates of 200-1000GSM. Sensor failure detecting sensors will detect the machine and stop machine automatically if any errors happen. The finished plates are collected and counted automatically, which can greatly save the labor costs.

High-speed paper plate machine is a piece of equipment used for the mass production of paper plates at a fast rate. It is designed to automate the process of cutting, shaping, and forming paper into plates, increasing efficiency and productivity. These machines can produce a large number of paper plates per minute, making them suitable for commercial operations such as restaurants, catering services, and packaging companies.

Increased production efficiency: A paper plate forming machine can produce a large number of paper plates in a short period of time. This helps to increase production efficiency and meet the growing demand for paper plates.

Cost-effective: Using a paper plate forming machine can help to reduce labor costs as it requires fewer workers to operate the machine compared to manual plate forming. Additionally, the machine can produce plates with minimal wastage, reducing material costs.

Consistent quality: Paper plate forming machines are designed to produce plates with consistent quality and shape. This ensures that each plate meets the required standards and customer expectations.

Versatility: Paper plate forming machines can be used to produce a variety of plate sizes and shapes, allowing manufacturers to cater to different customer needs and preferences.

Easy to operate: Modern paper plate forming machines are user-friendly and easy to operate. They come with intuitive controls and require minimal training for operators.

Environmentally friendly: Paper plates are more environmentally friendly compared to plastic or foam plates. Using a paper plate forming machine helps to promote the use of biodegradable and recyclable materials, reducing the environmental impact.

Increased profitability: By increasing production efficiency, reducing labor and material costs, and meeting customer demands, a paper plate forming machine can help manufacturers increase their profitability.

Reduced dependency on manual labor: Using a paper plate forming machine reduces the dependency on manual labor, which can be challenging to find and retain. This helps to minimize labor-related issues and ensures a continuous production process.

Improved hygiene: Paper plates produced by a machine are generally more hygienic compared to manually formed plates. The automated process reduces the risk of contamination and ensures a clean and safe product.

Scalability: Paper plate forming machines can be easily scaled up or down depending on the production requirements. This allows manufacturers to adapt to changing market demands and expand their business.

Cost-effective: Disposable paper plates are generally cheaper than other types of plates, such as plastic or ceramic. By producing your own paper plates with a machine, you can save money on purchasing plates for various events or businesses.

Eco-friendly: Paper plates are biodegradable and can be easily recycled. By using a disposable paper plate making machine, you can contribute to reducing plastic waste and promoting sustainability.

Customization options: With a paper plate making machine, you can create plates in different sizes, shapes, and designs according to your specific needs. This allows for customization and branding opportunities, especially for businesses or events.

Easy to use: Disposable paper plate making machines are typically user-friendly and require minimal training or expertise to operate. This makes it accessible for anyone to produce their own paper plates.

Versatility: Paper plates can be used for various purposes, such as picnics, parties, weddings, food stalls, and more. With a paper plate making machine, you have the flexibility to produce plates for different occasions and markets.

Overall, choosing a disposable paper plate making machine provides a cost-effective, eco-friendly, customizable, and versatile solution for producing paper plates.

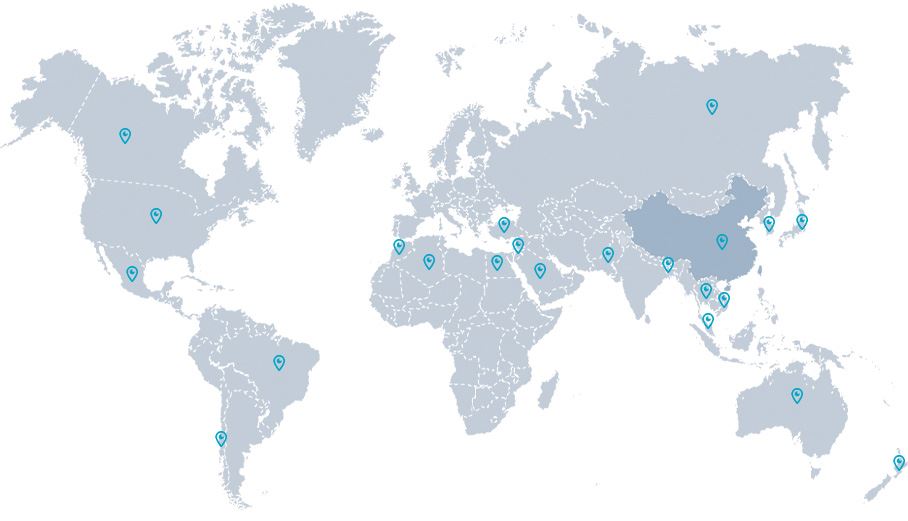

Mingyuan is a professional paper cup and paper plate making machine manufacturer and supplier in China established in 2009, providing high-speed paper plate machines, paper plate forming machines, and disposable paper plate making machines.

Rated Speed:120 ~ 140 pcs/min (7200-8400 pcs/h)

Paper Plate Size:2-12 inches (mold can be replaced)

Suitable Paper Weight:100-500 gsm

Power Source:380V, 50160HZ or other requirements

Total Power: 8.5KW

Rated Speed:100-120 pieces per minute can be produced

Paper Plate Size:3-16 inch (mold exchangeable)

Suitable PaperWeight:100-500 gsm (gram a square meter)

Power Source:380V 50Hz or other required

Total Power: 7 KW - 8.5KW

We use multi layers sucker which is better quality and not easily has more longer service life.

Better quality durable mould,longer service life,the mould design can be customize as customers requirement.

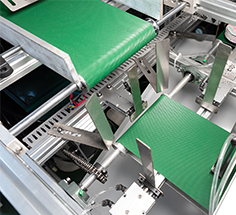

The finished plates are transferred by the conveyor which is easier for collecting the plate.

The counting & collecting system with sorting function can stack the finished paper plate in order,which is convenient for packing and save the labor costs.