In the process of paper cup production, choosing the right equipment is crucial to improving production efficiency and ensuring product quality. Our high-speed double turnplate paper cup machine MYC-120 has been significantly upgraded in many aspects compared to the traditional single turnplate machine OCM12. The following is a detailed comparison and improvement of each aspect:

1. Upgrade of paper pre-feeding system

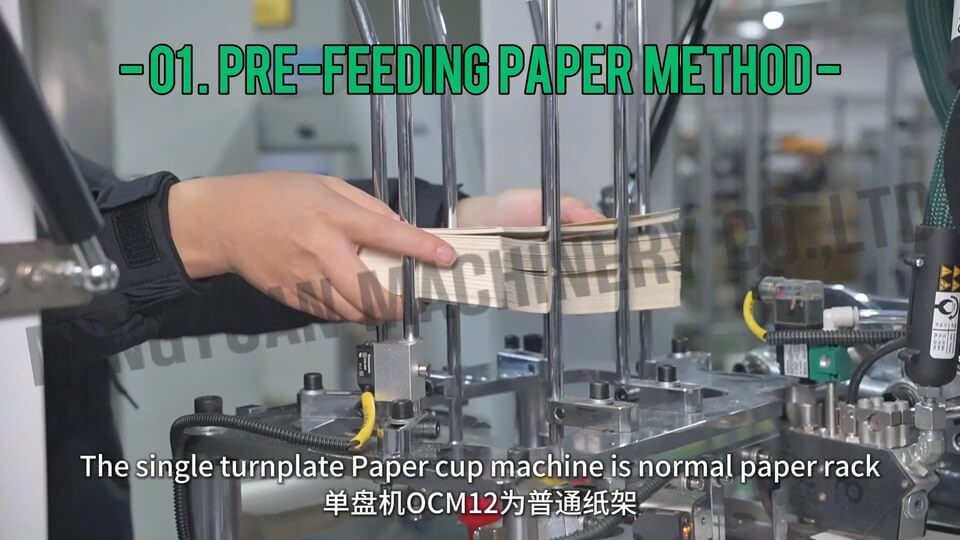

OCM12 single turnplate machine:

Equipped with ordinary paper rack, it requires manual continuous paper feeding. This operation is not only time-consuming and labor-intensive, but also prone to production interruptions due to human factors.

MYC-120 double turnplate machine:

An automated paper pre-feeding system is adopted to replace the traditional manual paper feeding method. The automated design of the pre-feeding system significantly improves production efficiency, reduces manual intervention, and ensures a smoother production process.

2. Improvement of paper feeding method

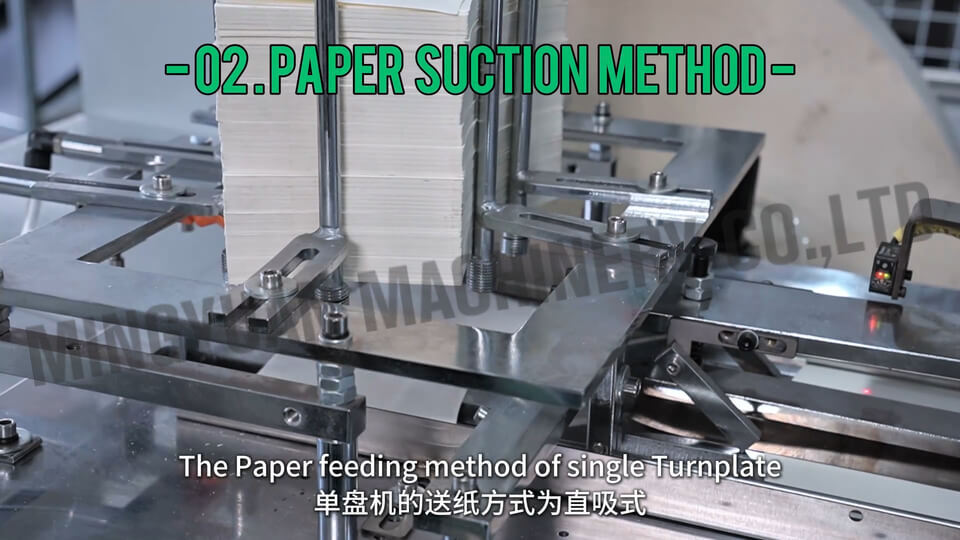

OCM12 single turnplate machine:

Uses direct suction paper feeding method, and transmits the paper fan to the production line through vertical adsorption. This method is prone to paper jams, resulting in an unsmooth production process.

MYC-120 double turnplate machine:

Equipped with an oblique suction rotary paper suction system, the paper fan is directly delivered to the runway, avoiding paper jams and ensuring smooth paper feeding.

3. Optimization of heating system

OCM12 single turnplate machine:

Equipped with 2 air blowing furnaces.

The air blowing furnace only provides heating when the paper cup passes by. The intermittent heating causes the sealing effect of the bottom of the paper cup to be unstable, which limits the increase in production speed.

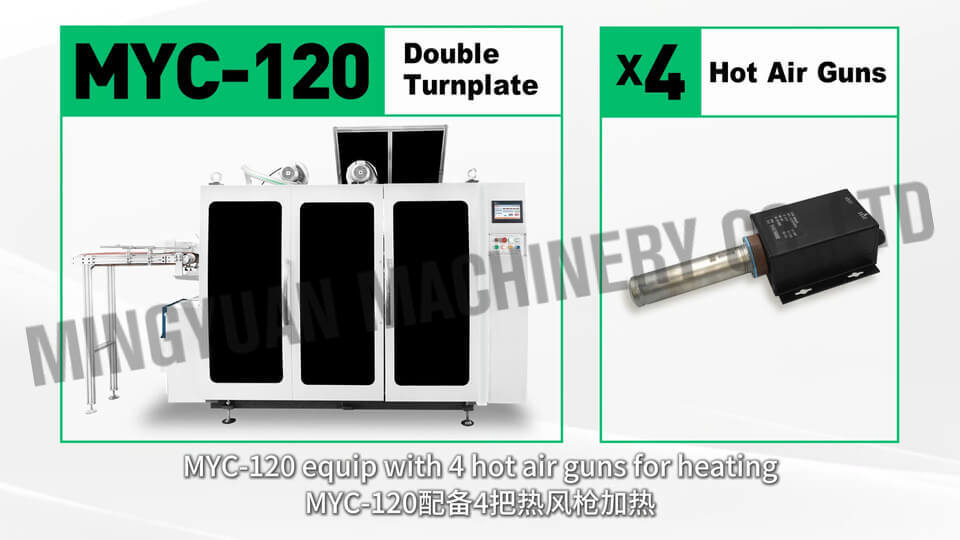

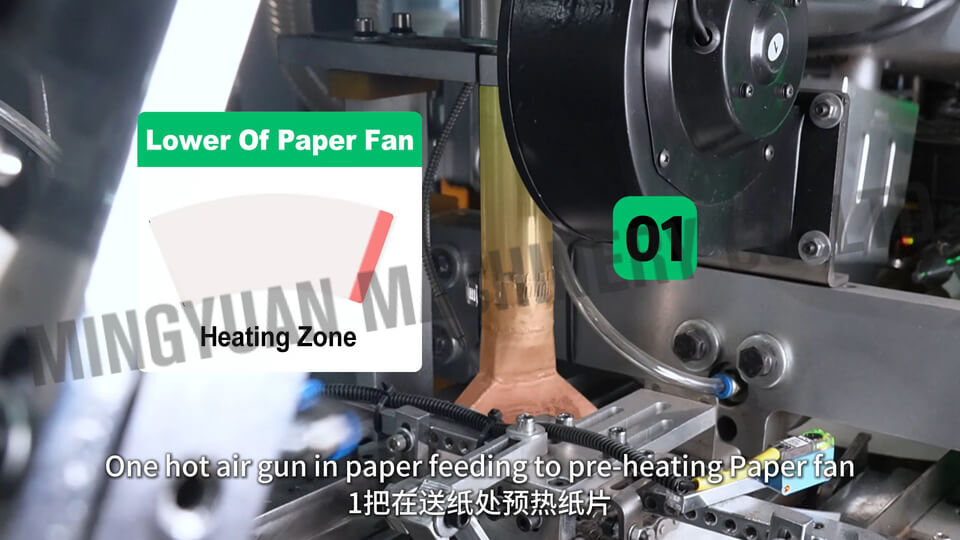

MYC-120 double turnplate machine:

Equipped with 4 hot air guns, it can quickly heat up and maintain a stable temperature difference, providing continuous heating.

One of the hot air guns is used to preheat the paper at the paper feeding position to ensure that the paper cups are more firmly bonded.

2 heat guns for bottom sealing;

The last hot air gun is responsible for the knurling process. These improvements significantly increase the stability and speed of production.

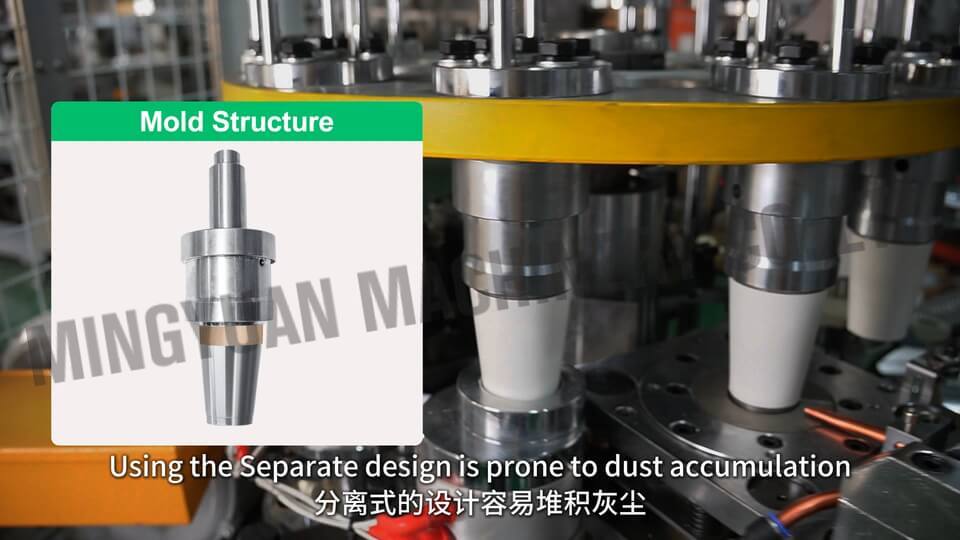

4. Improvement of mold design

OCM12 single turnplate machine:

The mold is made of steel, and the separate design is prone to dust accumulation, which affects the service life of the equipment.

MYC-120 double turnplate machine:

The mold is cast with aviation aluminum, and the one-piece design makes it more durable and easy to clean, effectively extending the service life of the equipment.

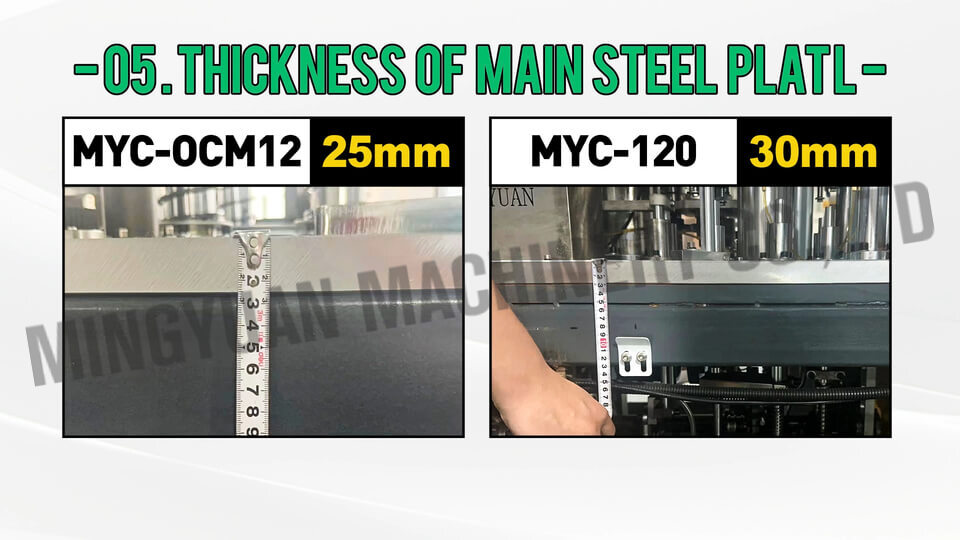

5. Increased thickness of main engine plate

OCM12 single turnplate machine:

The main machine board is 25mm thick, which can provide basic stability, but may be slightly insufficient when running at high speeds.

MYC-120 double turnplate machine:

The main machine board thickness is increased to 30mm, which enhances the stability of the equipment and supports higher operating speeds.

6. Lubrication system upgrade

OCM12 single turnplate machine:

The lubricant needs to be added manually, and the maintenance operation of each moving part is cumbersome and time-consuming.

MYC-120 double turnplate machine:

Equipped with an automatic lubrication system, all parts can be lubricated by operating the oil pump, which greatly improves the efficiency of daily maintenance and reduces downtime.

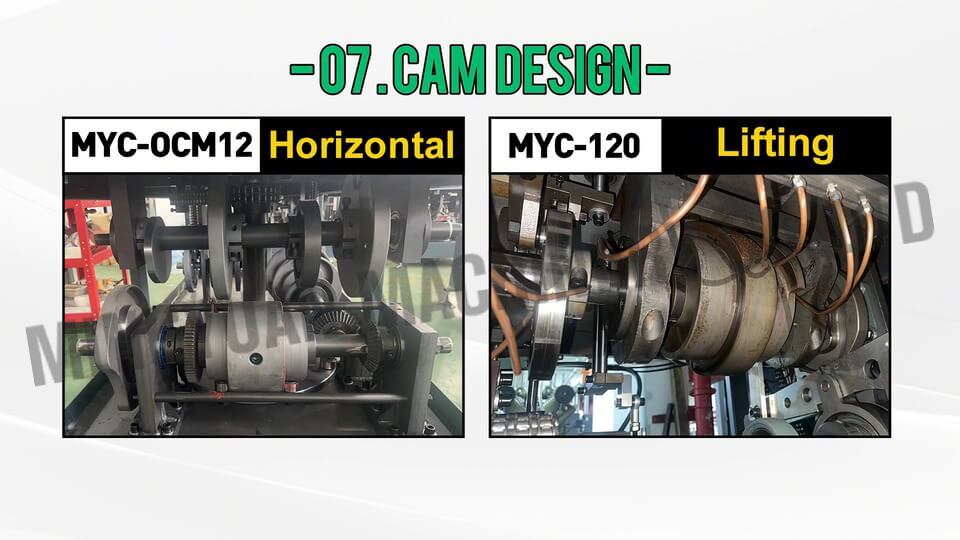

7. Optimization of cam design

OCM12 single turnplate machine:

It adopts horizontal open cam design, and its operating efficiency is low.

MYC-120 double turnplate machine:

It adopts overhead open cam design, which reduces the running resistance and stroke, thus effectively improving the running speed of the machine.

8. Improvement of curling process

OCM12 single turnplate machine:

Only one curling operation is performed on a single turntable, which limits the quality and aesthetics of the paper cup rim.

MYC-120 double turnplate machine:

Equipped with a special second turntable for double curling, it ensures that the rim of the paper cup is more delicate and beautiful, greatly improving the quality of the finished product.