The global paper packaging market is expanding at a 5.8% CAGR, with foodservice accounting for 38% market share. This growth is driven by two core technological elements: eco-innovations in paper cup fan blanks and intelligent upgrades in automated cup forming machines.

In the world of disposable packaging, paper cups are the main material for serving hot and cold drinks. But have you ever wondered how paper cups are made? A key component is the paper cup fan, which is a key raw material that forms the basis of every paper cup. Combined with advanced **paper cup machines**, manufacturers can efficiently produce high-quality, environmentally friendly paper cups.

This article explores what paper cup fans are, how they are made, and the role they play in paper cup production.

What is a paper cup fan?

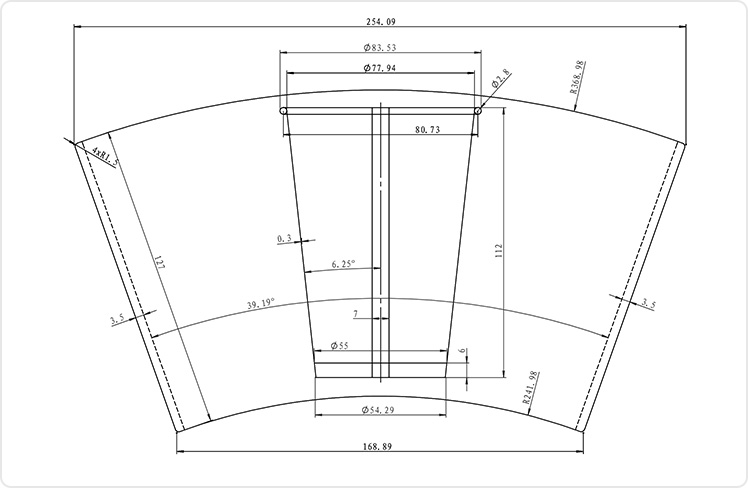

The paper cup fan is the main material used to make paper cups. It is made of multiple layers of wood pulp paper, which provides strength and durability. To make paper cups liquid-proof, the surface is coated with waterproof materials such as:

- **Polyacetate (PLA)** – A biodegradable coating derived from renewable resources such as corn starch, making it more environmentally friendly.

- **Polyethylene (PE)** – A common plastic coating that has excellent liquid-proof properties but poor biodegradability.

How are paper cup fans made?

The production of paper cup fans involves several key steps:

1. **Cutting** – Cutting large rolls of paper into smaller, more manageable sheets.

2. **Coating** – Applying a thin layer of PLA or PE coating to the paper to prevent absorption of liquids.

3. **Drying** – Drying the coated paper to ensure an even and firm coating.

These treated sheets (paper cup fans) are then fed into a cup machine to be formed into finished paper cups.

The Role of Paper Cup Machines in Manufacturing

Paper Cup machines automatically process paper cup fans into fully functional paper cups. Production stages include:

1. Printing (optional) – Some machines print patterns or logos on the paper before forming the cup.

2. Cup Forming – Rolling the fan-shaped cup body into a cylindrical shape and sealing it at the seam.

3. Bottom Sealing – Attaching the round cup

Conclusion: Technology-Driven Future

Paper cup manufacturing is transitioning from conventional processing to smart production. Strategic selection of fan blanks and intelligent forming systems, combined with lean management, enables 15%+ annual profit growth amid new sustainability regulations. Monitor EU PPWR updates and prioritize recyclable cup production lines.