product description

1. High Speed Gear System Paper Cup Machine

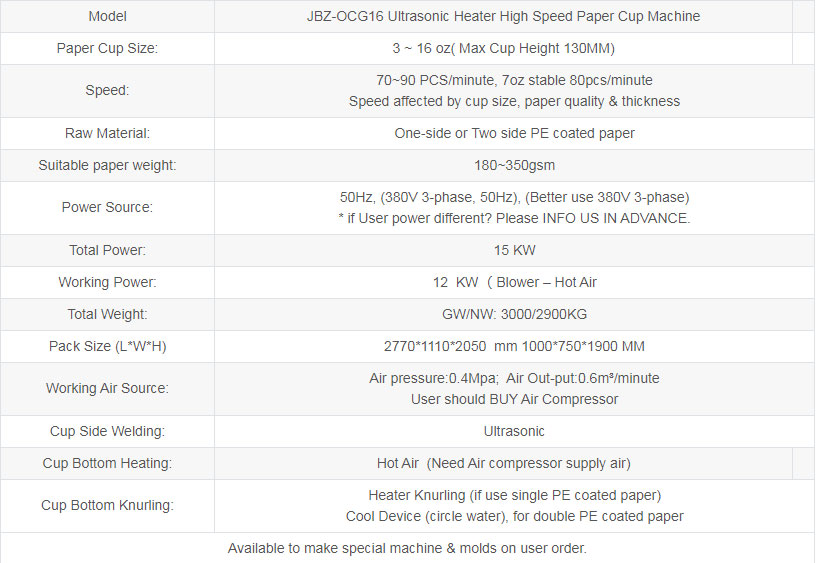

Technical Data

Advantage Design:

- 1, Adopt Open Cam for the dividing moving, compare with index gear box, easy maintenance, stable and reliable, easy replace broken parts.

- 2, Main mechanism and movement control by quality gears, which is more efficient than chain and axis.

- 3, Bottom disk straight punched and send to the cup body , less wastage and precision.

- 4, Robot straight lift the cup body to main mold.

- 5, Servo motor control the bottom disk, precision and reliable.

- 6, Automatic Oil Lubrication system, long life time.

- 7, All procedure sensor detect (sensors control all steps), Less wastage & fault, Reliable.

- 8, PLC Program computer control, easy operate, fault auto-stop and easy solution.

- 9, Quality electronic parts, bearing, material, machine life long.

- 10, With cup collector, one worker can run 2~3 sets machines.

2. Mechanical Type Paper Plate Machine with counting system

Brief Introduce :

ZDJ-1000 Mechanical type High Speed Paper Plate Forming Machine is developed and designed as the requirement of market. It is Mechanical Type which forming the plate control by the Cam no need air support, That is can help client save cost to buy big type air compressor( Save air) and Save the electric charge.

This Type machine give client two option: Single working station and Double working station. Client can according require to choose yourself suitable machine.

Main Technical Data:

- 1.Adopts Big Cam for control Mould forming the plate which no need air support, Help client save much electric charge and no need buy big air compressor.

- 2.Widely applied to produce paper plate, round or square plate with different specification and shapes.

- 3.Diameter of paper plates: 2—10 inch

- 4.Row material: Uncoated paper, PE coated paper, White Cardboard Paper, Ivory Cardboard Paper

- 5.Suitable paper weight: 120--300 gsm

- 6.Speed of making paper plates: 50--60 pcs per minute(single working station)

- 7.Total power: 3 KW

- 8.Power source: 220 V50 HZ,60 HZ or other needed

- 9.The Weight For Paper Plate Machine: Single working station 400KG, Double working station 700KGAppearance size(L x W x H): Single working station 3500*1200*1300MM Double working station: 3500* 2400 * 1300 mm

Advantage Design:

- 1,internally geared motor which provide mould running powerful and Long years span life.

- 2,Two times Paper feeding design is good for machine running stably at high speed

- 3,PLC intelligent control panel easy operation machine running

- 4,New Design Machine With mechanical structure which use Cam Control Mould Forming, The MainadvantageNo need air compressor support for forming the Plate

Company Profile

Established in 2009, Ruian Mingyuan Machinery Co., Ltd. is a professional manufacturer and exporter of paper cup machine, paper straw machine, paper burger box forming machine, cardboard machine, plastic cover machine, paper cake tray machine, various containers and packaging equipment. Design, development and production of companies.

With the company's quality products and excellent customer service, we have established a global sales network covering India, the United States, Germany, Poland, Romania, Jordan, Dubai, Saudi Arabia and other countries.

E-mail: mingyuanmachine@gmail.com Phone: 86-577-65567060